Yellow Tungten Oxide Producing Tungsten Carbide Powder

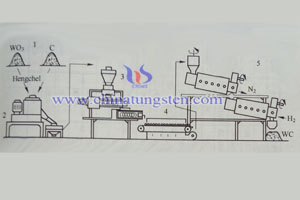

Yellow tungsten oxide carbonization method is one of the main applications of producing tungsten carbide powder. It can produce high quality ultrafine tungsten carbide powder, mixer, granulator, dryer and two rotary kiln furnaces are required as producing equipment.

In the below picture, 1 refers to raw material, 2 is mixer, 3 is granulator, 4 is dryer, 5 is rotary kiln furnace.

Yellow tungsten oxide carbonization method producing tungsten carbide powder process:

1.Mix yellow tungsten oxide with mass fraction 84% and carbon by mixer, granulate by granulator to particle with dimension 3mm, dry and mixed material Is obtained.

2.Move material to the kiln furnace and process the continuous reduction and carbonization, the original material changes during the reaction:

WO3→WO2.9→WO2.72→WO2.0→W→W2C→WC

WO3 heated in the first furnace under 1247℃ with N2, mixture of WO2.72, WO2 and W is obtained. Super fine crystalline appears in the transition process from WO2.72 to WO2. This is because WO2.72 is fine itself and volume shrinks when transit to WO2, density increases. When material contains carbon, it won’t form WO2(OH)2 which will accelerate crystalline growing, it avoids O2(OH)2 phase transition and growing of crystalline. Fine WO2 transits to super fine W crystalline will not change its grain size. In the second furnace under 1500℃ with H2 atmosphere, tungsten powder is carbonized, a little growth inhibitor is added to prevent enlarging of super fine tungsten carbide crystalline.

In the direct carbonized process, original yellow tungsten oxide and carbon affect carbon grain size. When YTO grain size is 2.6um and 1.8um, tungsten carbide particle size will not be affected by carbon, its grain size is around 0.5um. If apply YTO with grain size 1um and fine carbon, the obtained tungsten carbide powder grain size is 0.36um which is depended on YTO grain size.